Wanderful Loves

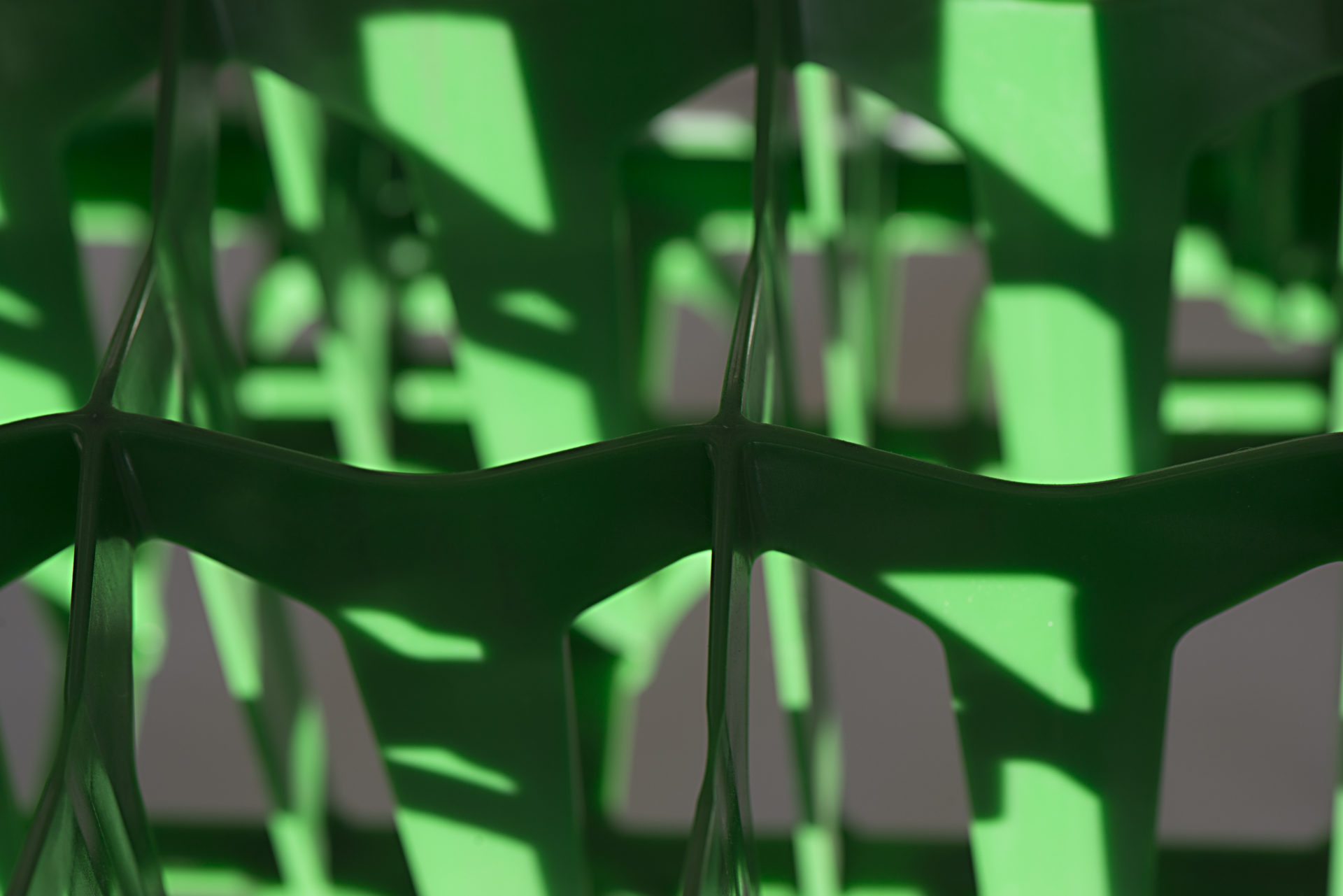

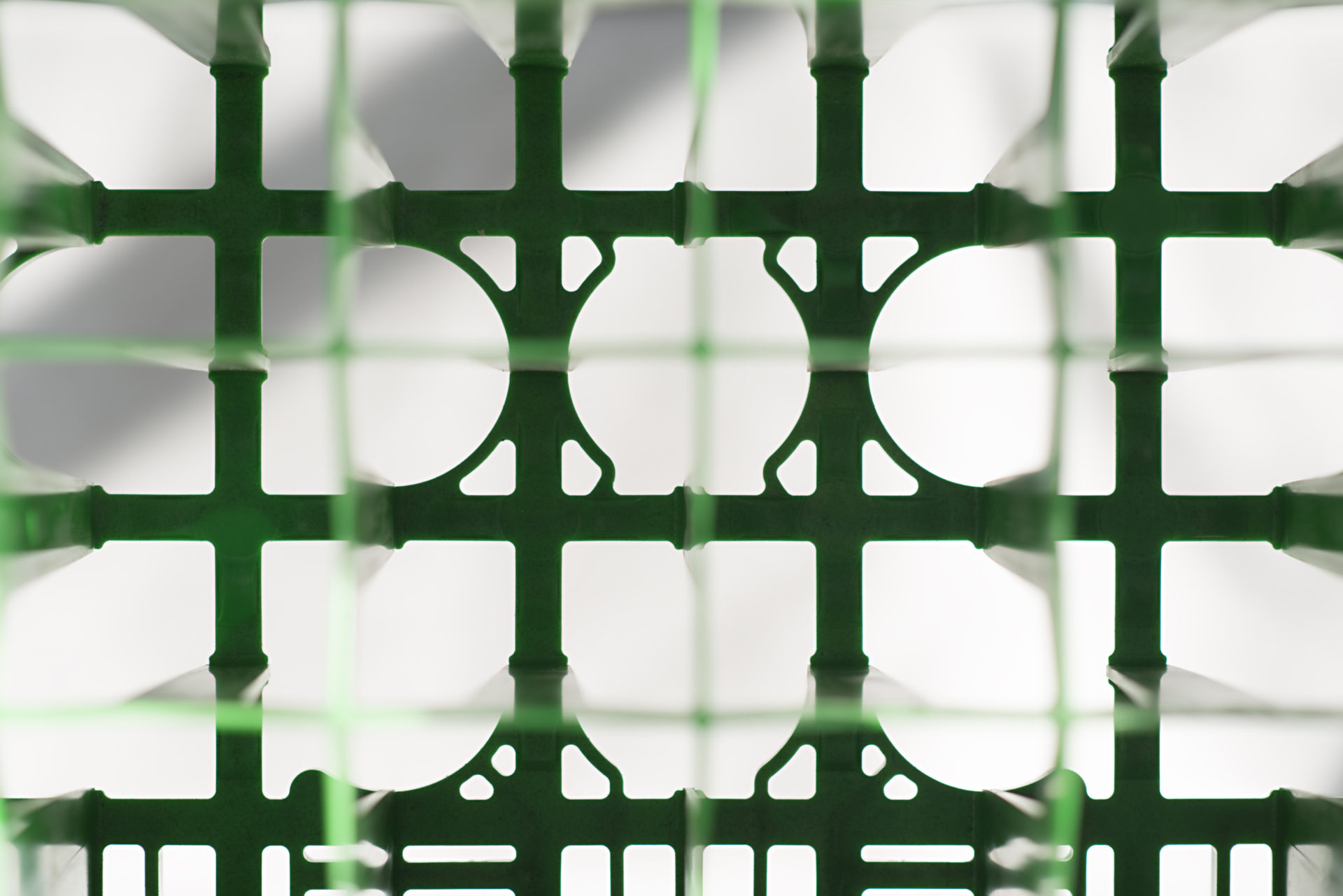

D.W. Plastics, the Bilzen specialist in the manufacture of crates for beer and soft drinks patented its first design, according to our records, in 1993. The Limburg producer was a pioneer in the technology used to make Injection Moulded products.

Clients include the Dutch beer giant Heineken, a major purchaser of these crates. D.W. Plastics works for more or less all the big beer producers, incidentally: Maes, Jupiler and Leffe to Super Bock or Carlsberg, these are just a few names from the portfolio. The Bilzen company has operated since 2013 under the new, international umbrella name of DS Smith Plastics.

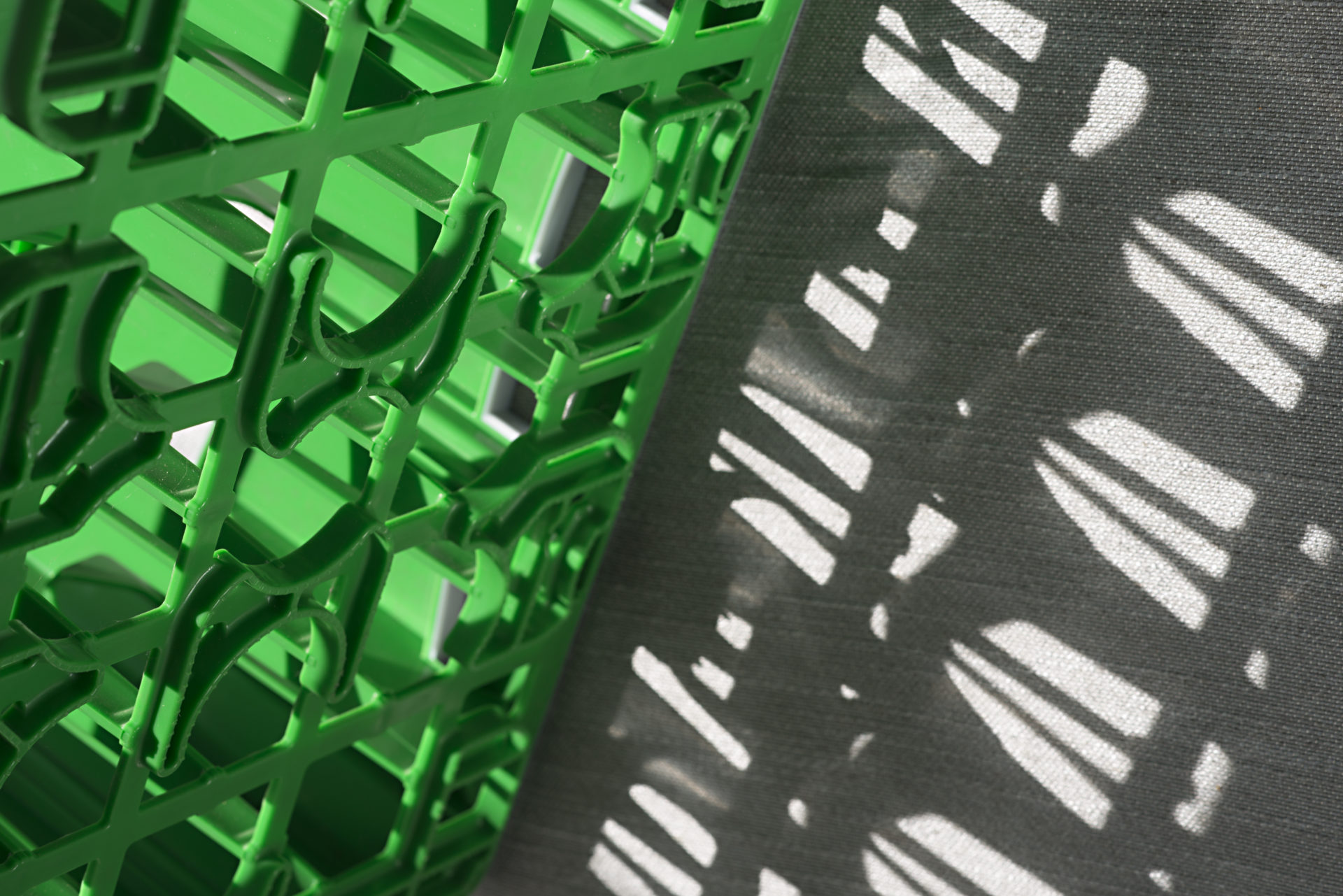

How innovative can a beer crate be? Well, a beer crate is often the most important point of contact between producer and customer. In-Mould Labelling (IML) is a popular process which we know not only because of Bilzen: there’s a good chance that your smartphone or laptop came in contact with this technology. It ensures a flawless end product which reduces costs and gives a pleasant visual finish. But the innovation doesn’t stop there. Radio frequency identification, RFID, is a wireless technology which automatically optimises inventorying, so products no longer have to be counted manually.

Apart from taking care of the transport of your favourite brew, the company also produces re-usable plastic crates and containers. In addition to these technological innovations, it has put much innovative thinking into the ways of stacking the crates. Thanks to the constant developing of ideas, the pallets and beer crates have never been so sturdy. With its turnover of around five billion Euros, in 36 countries, and supported by 26,000 employees, this Limburg innovation is a part of beer, worldwide.